WHO ARE WE?

Otimo – optimization

in the service of business

Otimo is first and foremost about people, top-class specialists in their fields. We turn our experience, know-how and passion into creating solutions for combinatorial optimization problems.

The team of experts

Otimo is a group of academic researchers, programmers and enthusiasts who have been working in various areas related to combinatorial optimization for many years.

Record-breaking algorithms

Our algorithms achieve some of the best results in the world for given optimization problems and compete as equals with the algorithms of technological giants from the USA or China.

Universal solutions

We create universal solutions that can be integrated into any system. We are not limited by programming language - both in the context of our libraries and APIs.

WHAT DO WE DO?

We create customized solutions for

combinatorial optimization problems.

We focus on areas related to logistics, warehouse management and transportation in the broad sense. Our algorithms achieve some of the best results in the world, allowing us to improve efficiency, automate processes and reduce operating costs, among other things.

WMS

We use our experience in creating world-class algorithms to optimize the operation of WMS systems. It is currently our core-business, and we specialize in areas related to order picking and solutions for JSP (job-shop scheduling problem).

APS

Another group of solutions we work with are APS systems. Our algorithms and libraries allow you to significantly improve advanced scheduling and planning processes so as to increase their precision and efficiency.

VRP

VRP optimization is embedded in OTIMO’s DNA. We dealt with it together and separately long before our company was founded, taking part in various projects and research works. We can pride ourselves not only on significant experience in this area, but also in world records.

WHY IS OPTIMIZATION SO IMPORTANT?

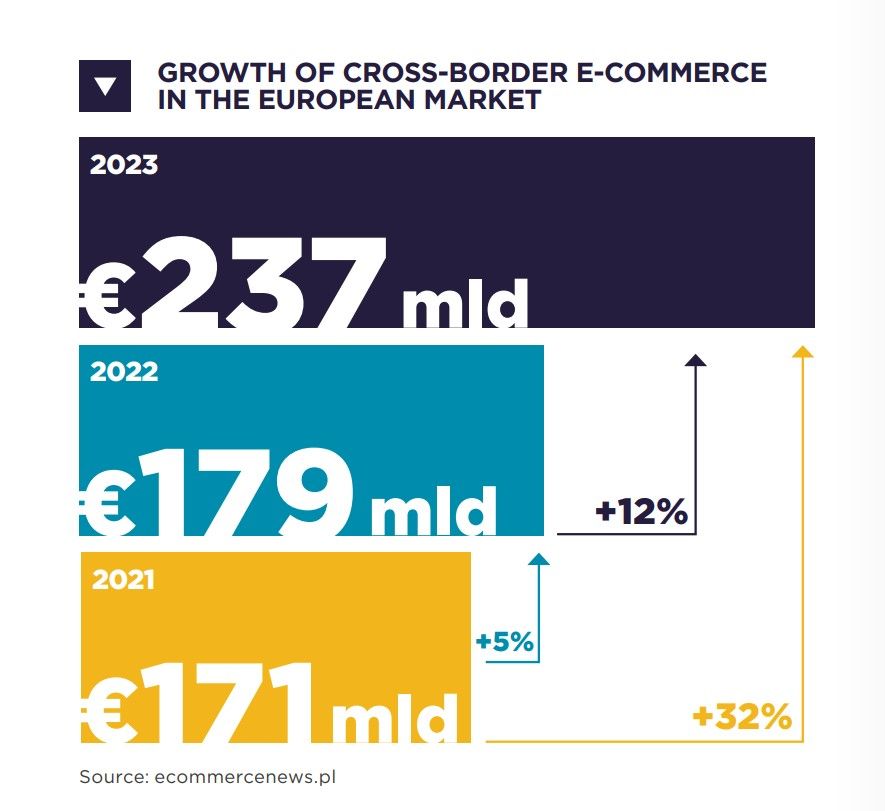

A glance at the statistics

provides a better understanding of the potential for automation and optimization of warehouse, production or transportation processes, and how large the demand is - especially after COVID pandemic and the e-commerce explosion.

of warehouses are currently planning to invest in automation (vs 33% in pre-COVID times)

of warehouses intend to invest in analytics and algorithms to optimize warehouse processes

of warehouse operating costs are attributable to the order picking process

even that much of their work time is spent by the order picker moving around the warehouse

of total operating costs in many industries are drivers’ salaries and fuel costs alone

on vehicle mileage is saved by implementing a system to optimize routes

INTERESTED IN THE INFORMATION ABOVE?

Learn more about:

News:

Otimo partnerem technologicznym w budowie innowacyjnej platformy spedycyjnej dla CSL Sp. z o.o.

Hycom x Otimo: IT synergy that accelerates logistics

Optymalizacja procesów magazynowych dla TME – globalnego lidera dystrybucji komponentów elektronicznych

Otimo dostarczy Rossmannowi rozwiązania do zaawansowanej optymalizacji logistycznej

Automation in Order Picking

Logistics and order fulfillment – trends 2025

Otimo at INTRALOGISTICA Poland Expo

Cross-border logistics

Black Friday 2024

WHAT DO WE CURRENTLY DO?

Our leading project

is WMS optimization

WMS systems are currently our core-business and it is the processes related to them that we devote most of our time to. The areas we particularly specialize in are order picking and solutions for JSP (job-shop scheduling problem).

Optimization of picking and order picking paths adapted to the specifics of the warehouse, its equipment with IT systems, machinery or human resources.

Incl.: Single Order Picking, Batch Picking, Multi-batch Picking, Wave Picking, Zone Picking, Smart picking / autonomous order picking.

The ordering of tasks in order to utilize resources as efficiently as possible: machinery, vehicles, skilled and unskilled personnel, service points and rooms.

Estimation and control over how many sorters, people and vehicles are needed to handle a given number of shipments per day.